AURUM NEWSLETTER

T-SENSATION

ABOUT

OUR TECHNOLOGY

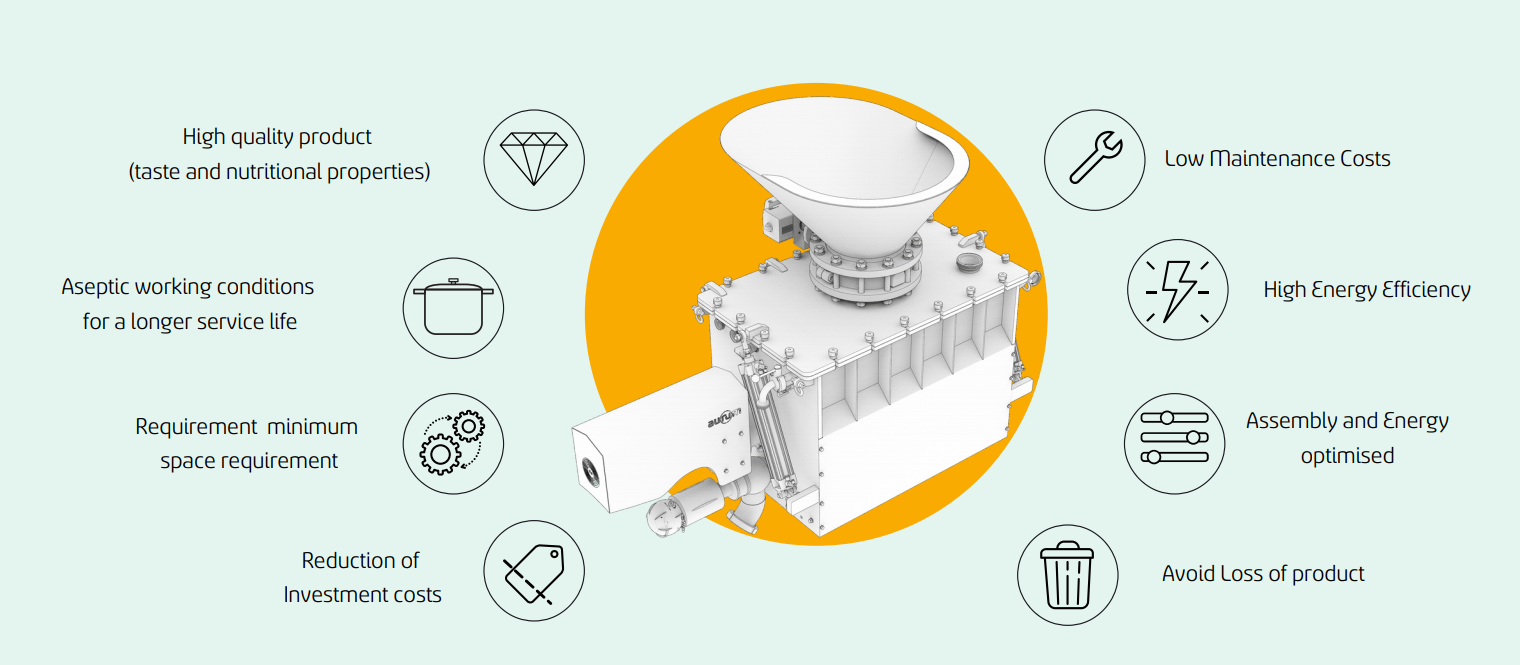

The key differential points of the technology are based on the:

- Even distribution of temperature within the cooker.

- Extended heat transfer scraped surface area.

- Reduced cooking time and keeping the organoleptic properties of the food.

- Capabilityto manage any degree of product viscosity.

- Aspetic cooking: we can aseptically package the product directly and inmediately after production without double heat treatment.

WHAT IS T-SENSATION

T-SENSATION VS OTHER REACTORS

- Extended Heating Surface

The heating surface of the T-Sensation is bigger than in the others the reactors, so the

heating and cooling power is much greater

- Pressure and Vacuum Working Conditions

T-Sensation can work under pressure and vacuum. The maximum design pressure in the

product zone are 2 bar (134ºC).

- No Fouling.

Our scraper system is designed so that the entire inner surface in contact with the product is scraped, preventing product sticking and loss of performance

- Non-stick Surface.

The surface in contact with the product can be non-stick treated with special FDA coating. T-Sensation is the only equipment that has this type of coating, which is essential to avoid contamination by starch, proteins, etc

- Self Cleaning System

Our scrapers system sallows automatic cleaning and does not require operators to clean

the equipment.

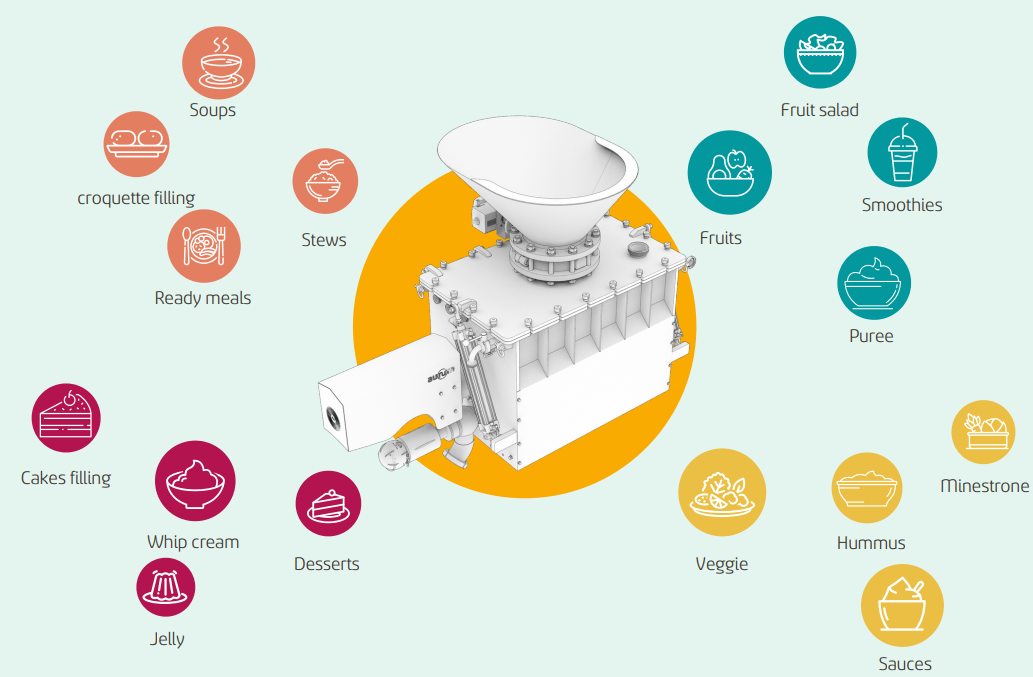

- Versatile Equipment

With T-Sensation the whole cooking process can be done with a single piece of

equipment.

- Food Safety

- Natural taste > Homemade recipes

- No additives/preservatives

- The production efficiency

- No hydratation requires for legumes

- Significant Cost savings

- Enery & Time saving

- Long shelf life

- Ambient storage

T-SENSATION

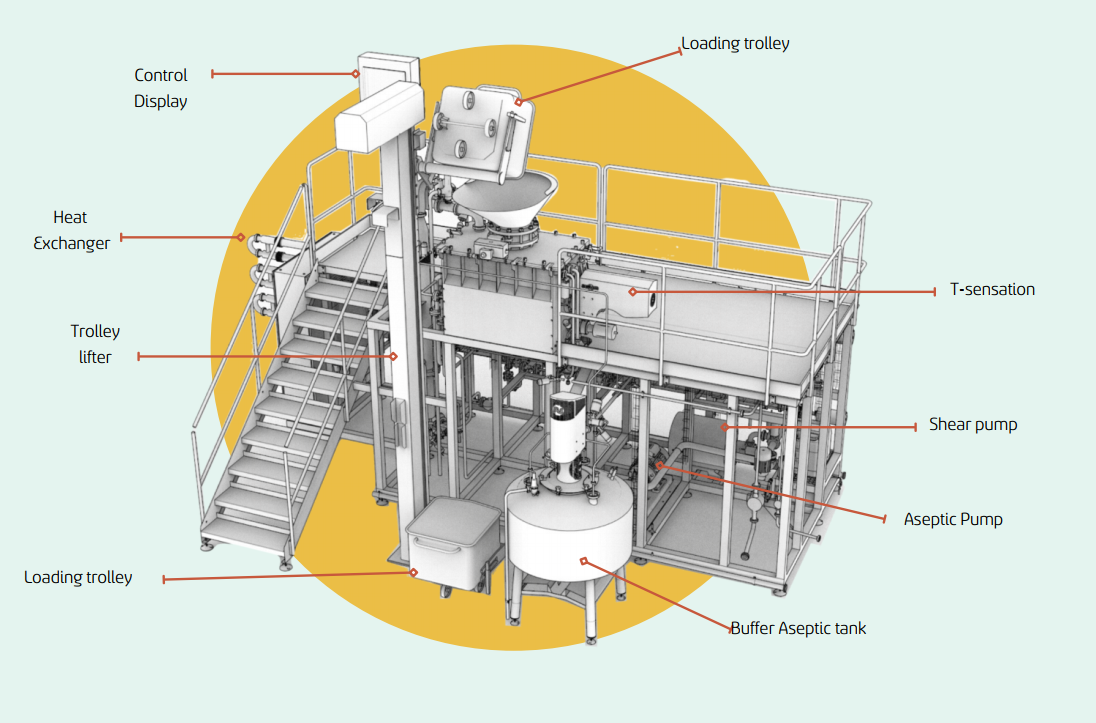

FLEXIBLE COOKING REACTOR LINE

T-Sensation® technology provides high efficiency heat transfer.

This flexible cooking line is capable of cooking everything from complex recipes to simple purees with a homemade taste.

It reduces cooking time and maintains the organoleptic properties of the food, with the possibility of cooking in aseptic conditions without additives and preservatives.

![]()

EFFIENCY MEANS SAVINGS

Cooking times are reduced 4-5 times VS a traditional kettle. 1000 kg 20 min VS 1000 kg 60 to 90 min

*According to recipe/preparation.

- Heat loss is reduced to one fifth.

- 1000 L tank at 100ºC of about 15.000 Kcal/hr

- For each load (20 minutes per load), the T-1000 will lose 6,000 Kcal. While the kettle will need 2 hours per charge and will lose about 30.000 Kcal

- In Euros, cost of 0,8 € per T-1000 load and about 4,0 € for a traditional kettle.

- Lower electricity consumption during the operation of the machine due to shorter process time.

- Labour cost less than 50% compared to traditional kettles, due to the reduction in the number of operators needed.

- Lower overhead charge per load produced, due to shorter process time.

- No autoclave cost in case of aseptic cooking & aseptic.