AURUM NEWSLETTER

HEAT EXCHANGERS

HOW THEY WORK

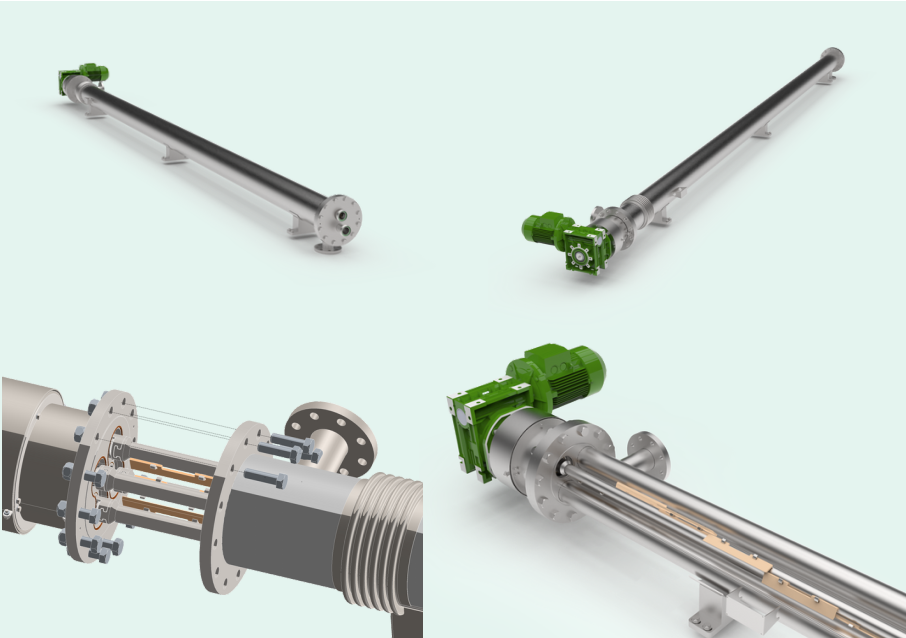

At Aurum Process Technology we have increased the efficiency of our tubular heat exchangers by applying corrugation treatments, which brings benefits to both the inside and outside of the tubes.

With this design we achieve higher levels of turbulence, doubling the heat transfer efficiency compared to smooth tubes, thus requiring less heat transfer surface area. This results in more compact solutions that require less investment.

Scrapped surface Heat Exchangers. consisting of a tubular bundle welded to a jacket. The product flows through the inner tubes in which a rotating bar with scraper elements are located. The service fluid flows through the space between the inner tubes and the jacket covering them.

RM series

The continuous scraping of the RM series heat exchangers allows the mixing of high viscosity products while eliminating fouling of each inner tubes. This ensures that the heat transfer area is clean at all times.

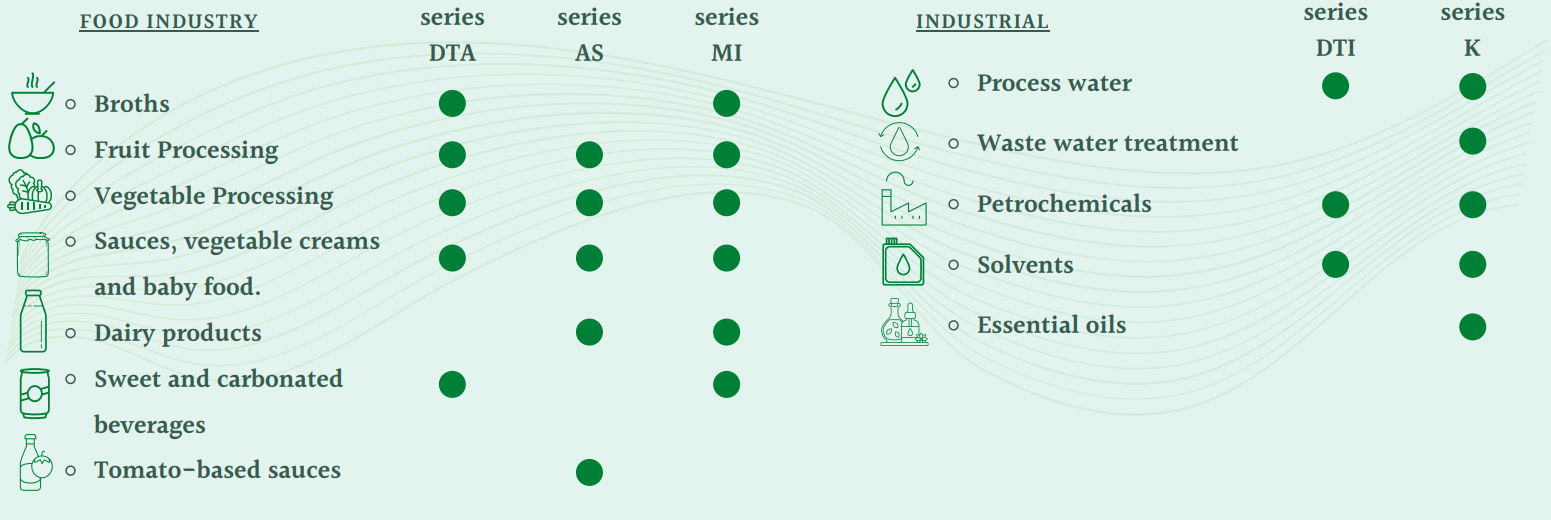

A HEAT EXCHANGER FOR EVERY APPLICATION

- AS series The triple tube or annular space heat exchanger is used

for viscous fluid applications. - DTA series The heat exchanger type DTA is a double tube heat

exchanger, with a design suitable for the food industry. Ideal for

fluids with large particles. - DTI series The heat exchanger type DTI is a double tube heat

exchanger, ideal for fluids with large particles. - MI series The MI series heat exchangers are heat exchangers with

stainless steel inner tubes and jacket for food use. - K series K series heat exchangers are heat exchangers with

stainless steel inner tubes and jacket for industrial use.

USES & APPLICATIONS

Uses:

- To raise the temperature of a fluid, using a hotter fluid

- To cool a fluid using another fluid that is at a lower temperature.

- Condensing gases

- Evaporating liquids.

Advantages of the tubular heat exchangers:

- Low maintenance costs.

- High working pressures.

- High operating temperatures

- Processing of fibres or particles

- High safety in aseptic processes

- Easy inspection and disassembly

Applications

Food Industry, with special with special attention on finishes, CIP cleaning and drainability of the equipment.

Pharmaceutical applications for the pharmaceutical and biotechnological industry, where roughness certification plays a key role, where design is especially aimed at avoiding cross-contamination.

Industrial applications for the pharmaceutical and biotechnological industry, where roughness certification plays a key role, where design is especially aimed at avoiding cross-contamination.