Fragmentation of cereals and pulses and starch separation

In the last few years, we have developed several technologies for processing and fractioning of grains & legumes with the best results in terms of maintaining functional properties of fractions and efficiency. Our highly effective processes allow optimizing the yield and concentration of fractions in order to get the best out of each grain or legume. All this with minimal energy and water consumption, eco-friendly technology and integration of a full CIP system. Next we describe the processes in which we are specialized.

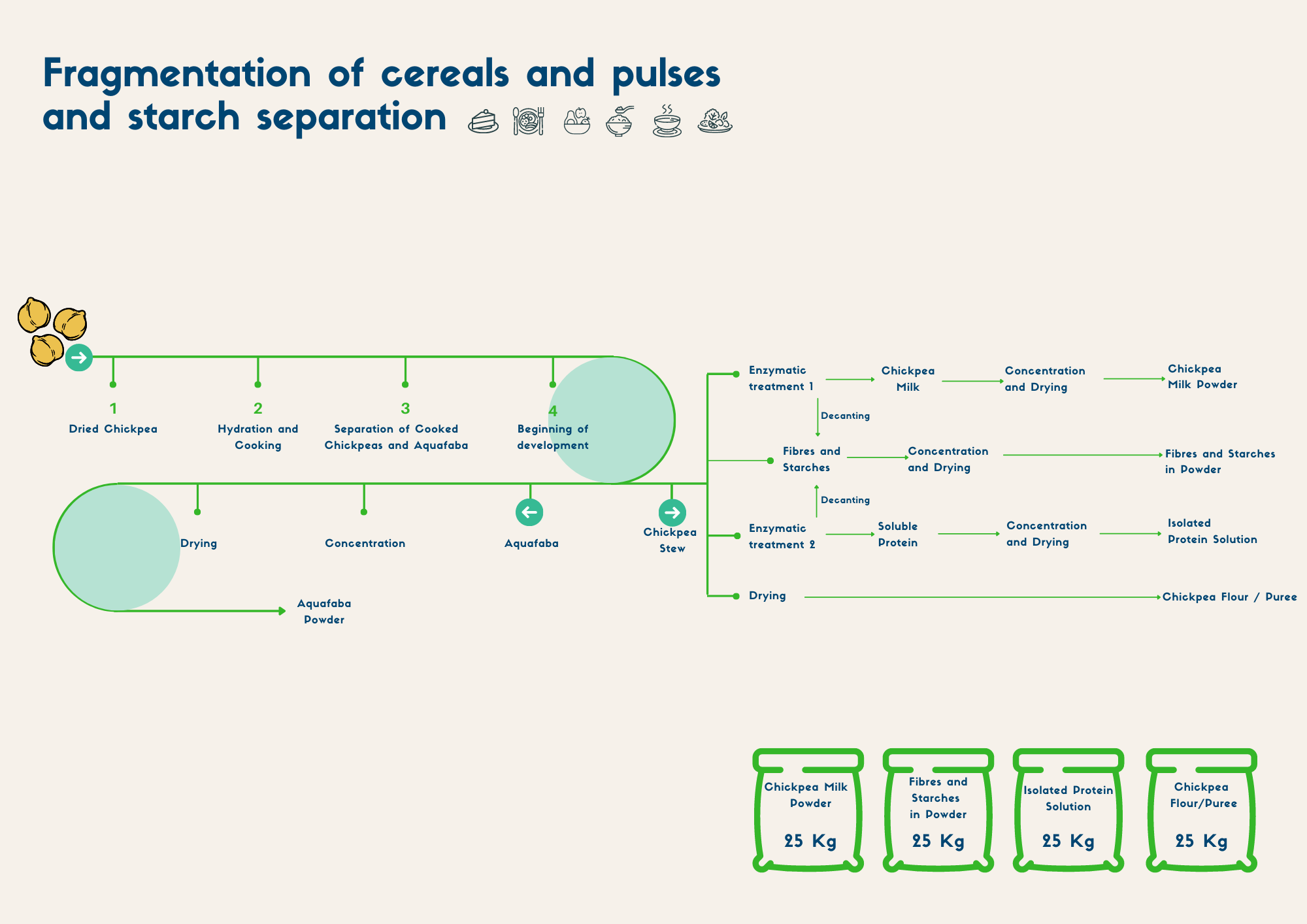

PROTEIN, STARCH, FIBRE SEPARATION – FRAGMENTATION OF LEGUMES & CEREALS

We offer first-class engineering service and taylor-made solutions integrating the latest technologies from extraction, separation and purification of proteins through concentration and drying with spray dryers in order to get plant-based protein powders or isolates and other functional ingredients. We design and build both dry and wet protein extraction plants and we apply both precipitation and membrane filtration technologies depending on the specific needs of our clients. Our innovative technology with the help of micro- and nanofiltration, enzymatic & biochemical treatments makes possible to reach a much lower CAPEX and OPEX than using the standard precipitation technology.

With the help of our state-of-the art technology we can reach a high recovery level of the best quality products like:

- Plant-based protein concentrate or powder

- Soluble fibre

- Starch

- Natural sugar

- Plant-based drinks (oats/chickpeas “Milk”, etc.)

With our vegetable proteing manufacturing technology you can elaborate not only vegetable protein concentrates and other natural ingredients, but also animal feed products.

ACCELERATED HYDRATION OF LEGUMES & CEREALS

- Makes possible to hydrate any legume in 90 minutes(volumes from 200 kg to 3000 kg), while in case of a normal hydration line you need 12 hours for this process and large silos. With our technology, you can do continuous hydration withouth being limited by batch production. What we offer you is saving time, space and investment in large installations.

- Aquafaba extraction from cooking water of legumes.